Curing-chamber

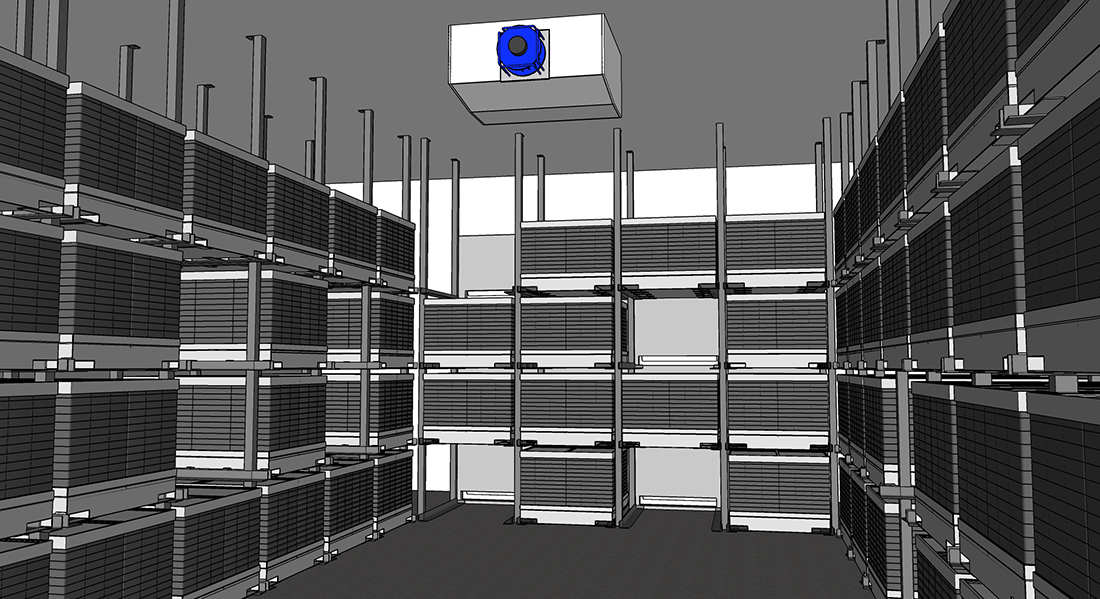

The Curing-chamber, which can be opened by an automated sliding door, consist of racks where the Sandwich-units are placed on with a forklift.

Curing Chamber System

The Curing-chamber is made with double walls and a double ceiling. These double walls are necessary to make the airflow possible. A small ventilator next to each Sandwich-unit sucks the air top-down through the cannabis. From there the air flows through the double walls and the ceiling to a cooling/warming unit which brings the air to the desired temperatures and humidity levels. After that multiple vans pump the air through an airbag, to spread it evenly in the Curing-chamber.

The curing process takes approximately four times longer than the drying process. Therefore, the Curing-chamber offers space to four times more Sandwich-units then the drying cells do.