MANAGING YOUR – ABC – HVAC CONTROLLER

Our promise to you – is also our mission: labor costs ↓ Quality ↑ Control ↑

For you, being the manager, on this page the magic actually begins and ends. We are proud of our ‘ABC’ HVAC -system. Our HVAC controller is made and maintained in-house. It holds over 35 years of stable and proven innovations. The system consists of a processor and a software program. It is implemented in thousands of control systems – in various agricultural sectors worldwide – in all 6 continents – over 50 countries. With our world-renowned technology, we guarantee that you can set optimal drying conditions for your own cannabis business process and gain substantial benefits. The ABC-processor allows you to dry as fast or

slow as desired drying – completed in 3-15 days.

How is the ABC -HVAC Controller used?

Our ABC processor and software enable easy management of the drying and curing process every step of the way. You can set it the way you want. You can easily manage the process on a touch panel just outside the rooms or manage on a remote device (tablet, laptop, mobile phone) on a holiday resort.

- Adjust the temperature, absolute/relative humidity and airflow.

- Flexibility: You can create presets for various processes and special strains.

- Our technical engineering department can produce tailormade processes, if needed.

- MCM module: control the ABC-processor from a tablet or mobile phone (optional).

- PC software: operate the ABC-processor from your PC.

- Real-time and immediate support is given by our own support engineers via your pc with TeamViewer.

- SMS alert (optional).

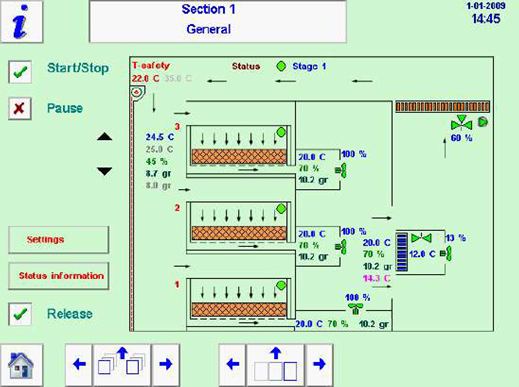

Example of a preset cross section with 3 sandwich units

Curing during drying with the Auto-Pause-function:

A special feature has been implemented in the ABC-processor to make curing during drying possible: The Auto-Pause function.

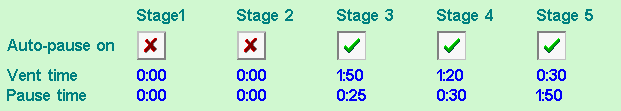

The Auto-Pause function allows the user to set a ‘Vent time’ and a ‘Pause time’ for each stage of the drying process. The Vent time is the time that the ventilator is running and the Pause time is the time that the ventilator is not running and there is no airflow. In the moment where there is no airflow, the moisture content in the cannabis comes in equilibrium with itself, making curing simultaneous with the drying process.

Example of a preset in the Auto-Pause menu

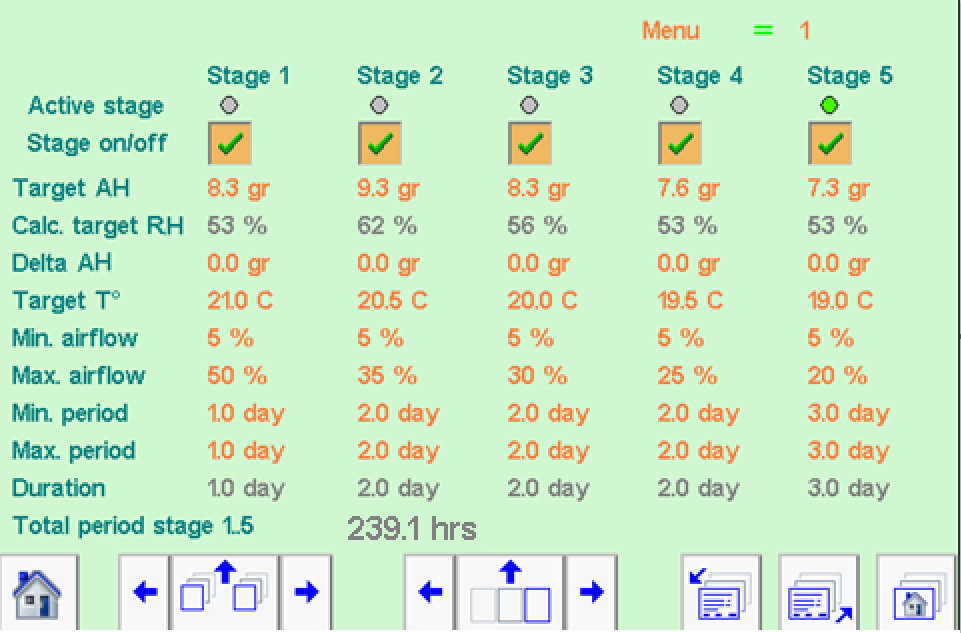

Example of a preset with 5 stages