How Does it work?

after harvesting the wet trimmed or bucked cannabis is placed in cannabis trays (Canna-Trays) by an operator. He/she puts every full canna-tray in a “Sandwich Unit“.

What is a Sandwich Unit?

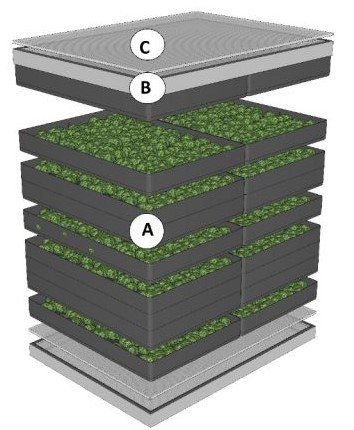

A Sandwich Unit is consist of filters and trays:

a. First, at the bottom is a layer of a HEPA H13 Filters and a Filter Pad.

b. Second, two piles of cannabis trays are placed on the filter.

c. On top a final layer of HEPA H13 Filters and a filter pad is placed.

A Sandwich Unit is build in all of our products:

- Drying Cabinet, (see video)

- Mobile Drying Pallet

- Ventilation Pallet (a full pallet is placed in a Drying Cell by a forklift, see video).

When the drying system is filled with cannabis, the operator activates the automated drying process (ABC processor) on a device, like a

tablet/mobile phone / a LED-monitor in the drying room itself, or computer in the office. The whole drying process can be controlled from anywhere on the world in a safe VPN connection.

With this cannabis drying method every single bud gets a – constant – controlled – top-down – evenly spread – 100% clean flow of process air – immediately after the bud is put in the cannabis tray and the tray is placed in the sandwich unit.

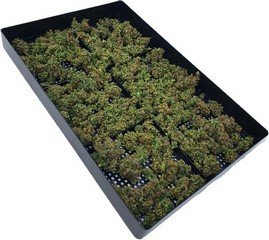

CANNA-TRAY

A Canna-Tray is where the cannabis is placed after harvest. Each Canna-Tray theherbcentre is divided into six low compartments (see image) preventing the cannabis from moving around and to make sure all the cannabis is evenly dried.

A Canna-Tray is made of an anti-static ABS thermoplastic compound. The anti-static compound prevents the plant material from sticking to the tray.

Each Canna-Tray has 1944 round holes of 6 mm (0.24-inch diameter) in the bottom. The holes ensure a continuous and equal top-down flow of controlled and cleaned process air throughout the duration of the drying (& curing) process.

Cannabis Tray “Canna-Tray”

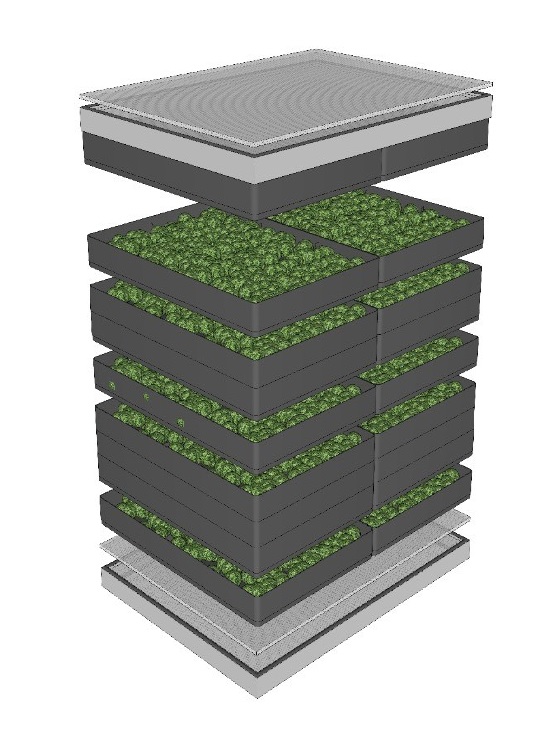

SANDWICH UNITS

With the www.cannabis-drying.com TOP-DOWN SANDWICH DRYING METHOD, every single bud gets a constant – controlled – top-down – flow of process air. The process air is evenly spread between all buds. This is done with Canna-Trays and filters. Get more information about the best online casinos for real money. These are stacked on top of each other as a sandwich.

The filters make sure that the cannabis remains in a clean environment.

Graphical view of one Sandwich-unit.

(By definition a sandwich unit is a closed clean and tight box. To explain the system we show it open here)

HEPA FILTER (filterclass H13)

To get the best clean air conditions — eliminating all risks: viruses, pests etc. Cannabis-Drying.com uses two types of filters: a HEPA (nano) filter and a filter pad.

The High Efficiency Particulate Air (HEPA) filter is made of micro-glass fiber sheet, meeting the highest European and U.S. standards. HEPA filters are used for specific clean cells in hospitals, pharmaceutical, nuclear and micro-electronics industry.

Hepa-filter

PALLET FOR DRYING CELL

A Pallet-sandwich is built on the Ventilation Pallet. A Pallet-sandwich consists of 4 sandwich units, placed on a Ventilation Pallet. The Ventilation Pallet ensures easy, safe & efficient transport with a forklift.

Properties of the Ventilation Pallet:

- Made of Stainless steel.

- Front has 2 openings for easy & efficient transport by a forklift.

- The back has big openings for process air to leave the pallet sandwich.

- Designed in such way, that the air is evenly distributed over the 4 sandwich units.

Ventilation Pallet is the holder of 4 Sandwich Units

when working with drying cells

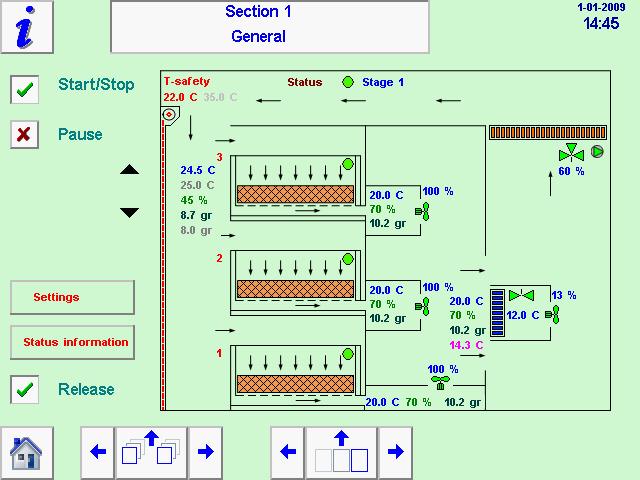

MANAGING YOUR – ABC – HVAC CONTROLLER

For you, being the manager, on this page the magic actually begins and ends. We are proud of our processor controller: the ‘ABC’ HVAC -system for Cannabis. Our Cannabis HVAC controller is build and maintained in-house.

The ABC system consists of a CPU / processor and a software program. It is suitable for Windows, Unix and Apple systems. It is a stable, state-of-the-art system; holding over 35 years of stable and proven innovations.

It is implemented on thousands of control systems – in various agricultural sectors worldwide -, in all 6 continents – over 50 countries. With our world-class technology, we can guarantee that you can set optimal drying conditions for your own cannabis business processes and gain substantial benefits.

How is the ABC -HVAC Controller used?

Our ABC processor and software enable easy management of the drying and curing process every step of the way.

Example of an ABC Controller page

CANNABIS-DRYING METHODS COMPARED

Most facilities still dry their cannabis by hanging the whole plants or stems of the plants upside down in a conditioned room. With our Top-down drying method, wet trimmed or bucked cannabis flowers are placed in Canna-Trays.

After a study that compared the Top-down drying method with hang drying, no differences in terpenen and cannabinoid content could be found. Whilst the Cannabis-Drying.com Top-Down drying method is 90% more space-efficient,