Results Lab tests Strain 1

Strain 2 - Results Lab tests

Strain 3 - Results Lab tests

Hang Drying Versus Top Down Drying – Analysis

The drying process of cannabis is one of the most important processes in the production of cannabis, but it is also the most overlooked process in the cannabis industry. Most facilities still dry their cannabis by hangings stems of the plant upside down in a drying room. Cannabis-drying.com developed a new drying system where the bucked or wet trimmed flowers of the cannabis are placed in Canna-Trays and a ventilator sucks the conditioned air Top-down through the Canna-Trays.

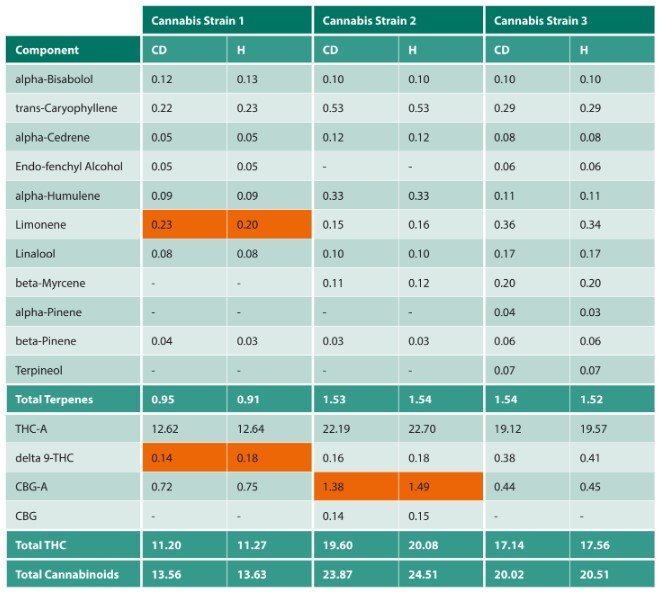

Results with regard to the terpene and cannabinoid content of the flowers that were dried with Cannabis-Drying.com’s system were compared to flowers that were dried by hanging the stems upside down. Both systems were placed in the same drying room, so the temperature and humidity of both drying methods were the same, making the results comparable. Very few differences in cannabinoid and terpene content were found. The bucked flowers in the Canna-Trays consume 89% less space than the hanging plants in the drying racks.

Cannabis-Drying.com’s testing unit in a drying cell with hanging plants

Table 1: Overview of the Cannabinoid and Terpene contents of cannabis-drying.com’s test unit (CD) and hang drying (H) per cannabis strain. On the left side,

all the components present are listed. The numbers show the amount of the component present in percentages (%). Orange boxes indicate significant

differences between the amounts per component between treatments within one cannabis strain.

Benefits of Top-Down Canna-Tray drying

- No wet spots will show on the cannabis, preventing the activation of mold and bacteria.

- Top-Down Canna-Tray drying is 85-95% more space-efficient than hang drying.

- Cannabis-drying.com’s systems for Top-Down Canna-Tray drying offer a precise control of temperature,

- humidity and airflow – allowing the user to perfectionate the drying process.

- Cannabis-drying.com’s ABC-processor allows the user to dry in 3 to 15 days, depending on the chosen settings.