Drying cell

The Drying Cell is made for easy handling of large quantities of cannabis.

Drying cells

Properties of the Drying Cell:

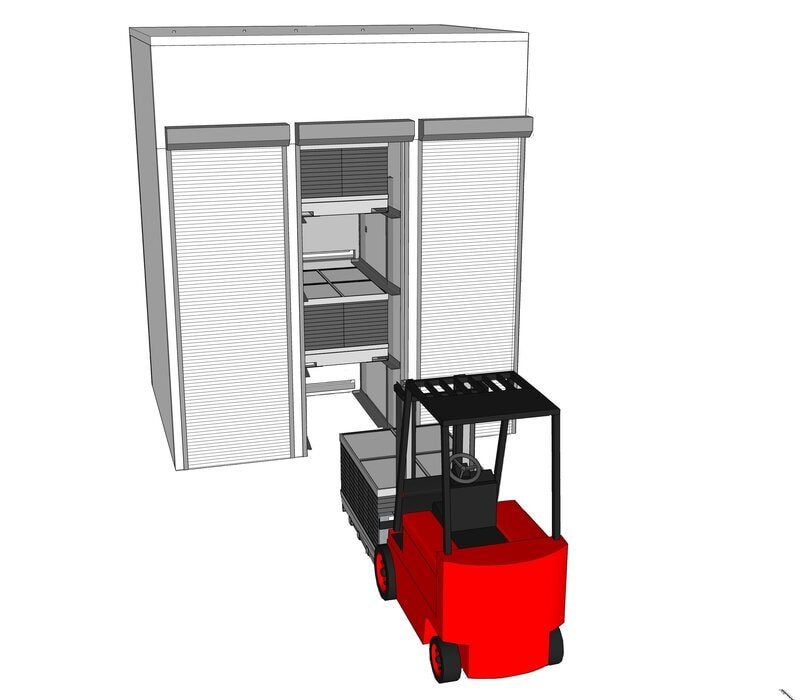

- Central in the Drying Cell operation is a forklift carrying a pallet-sandwich.

- Capable of drying 75-92kg (165-203lbs) per drying cycle, depending on the chosen configuration.

- Easily scalable.

- Easily cleaned.

- Temperature can reach 14 to 28°C (57-82°F).

- Humidity levels can be controlled from 30-90%.

- Airflow is set to a desired volume (m3/ft3)

For recreational cannabis.

Drying cells can be used for curing as well.

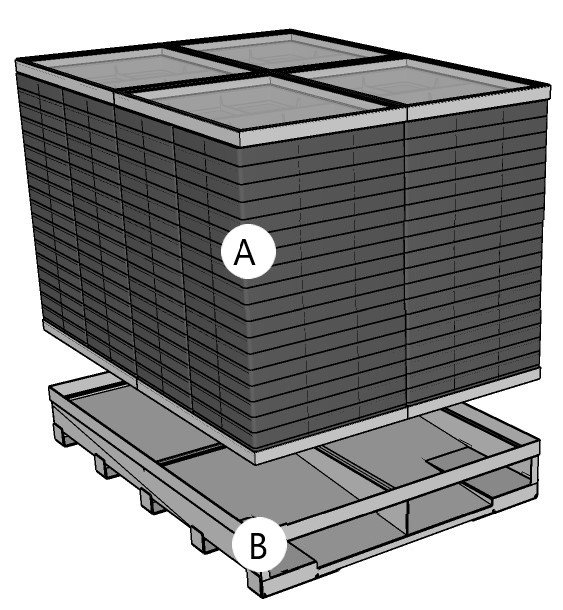

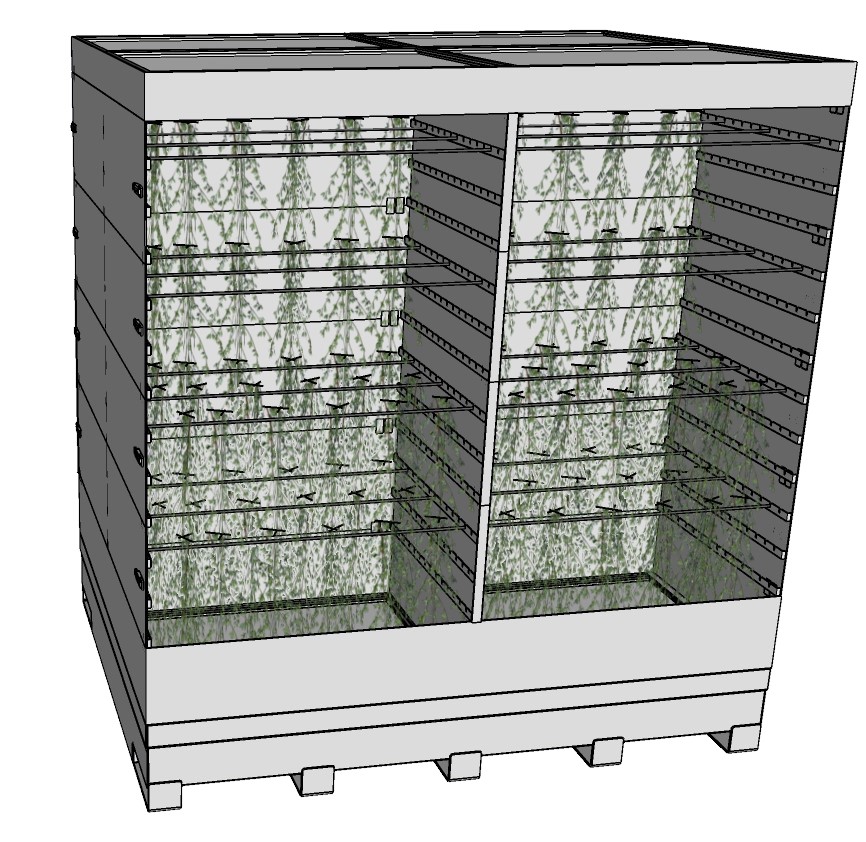

In the drying cells, the sandwich units are stacked on a ventilation pallet. The pallet with 4 sandwich units is called a pallet sandwich.

Components of a pallet sandwich

A: 4 sandwich units with 24-58 Canna-Trays

B: Ventilation pallet

Overview of a pallet sandwich

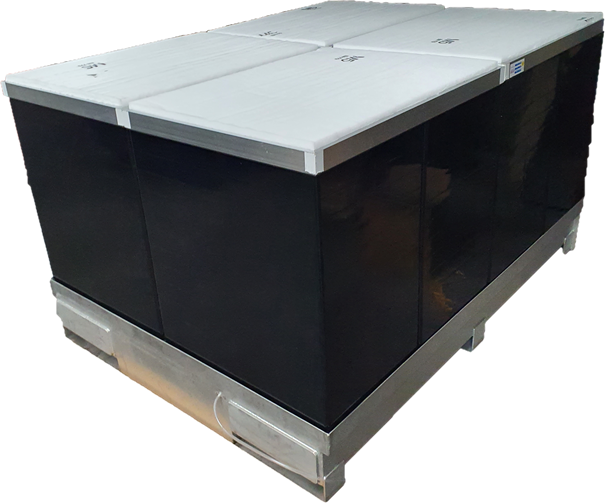

B. The Ventilation Pallet

The Ventilation Pallet holds 4 sandwich units, making it a pallet sandwich. The Ventilation Pallet ensures easy, safe & efficient transport with a forklift.

Properties of the Ventilation Pallet

- Made of Stainless steel.

- Front has 2 openings for easy & efficient transport by a forklift.

- The back (see the uper photo) has big openings for process air to leave the pallet sandwich.

- Easy to clean.Size: 1600x 1220x 240 mm (65 x 48 x 9.5″)

- Net weight: 110 kg (243 lbs.)

- The upper side is open, 4 HEPA-filters sets exactly fit in here.

- Designed in such way that the air is evenly distributed over the 4 sandwich units.

How is the Ventilation Pallet used?

- 4 HEPA filters with filter pads are placed in the Ventilation Pallet.

- 8 piles of Canna-Trays are placed on the filters.

- 4 HEPA filters with filter pads are placed on the piles of Canna-Trays. The filled Ventilation Pallet is called a Pallet-sandwich.

- A forklift places the Ventilation Pallet in the drying cell.

Ventilation pallet

Pallet sandwich

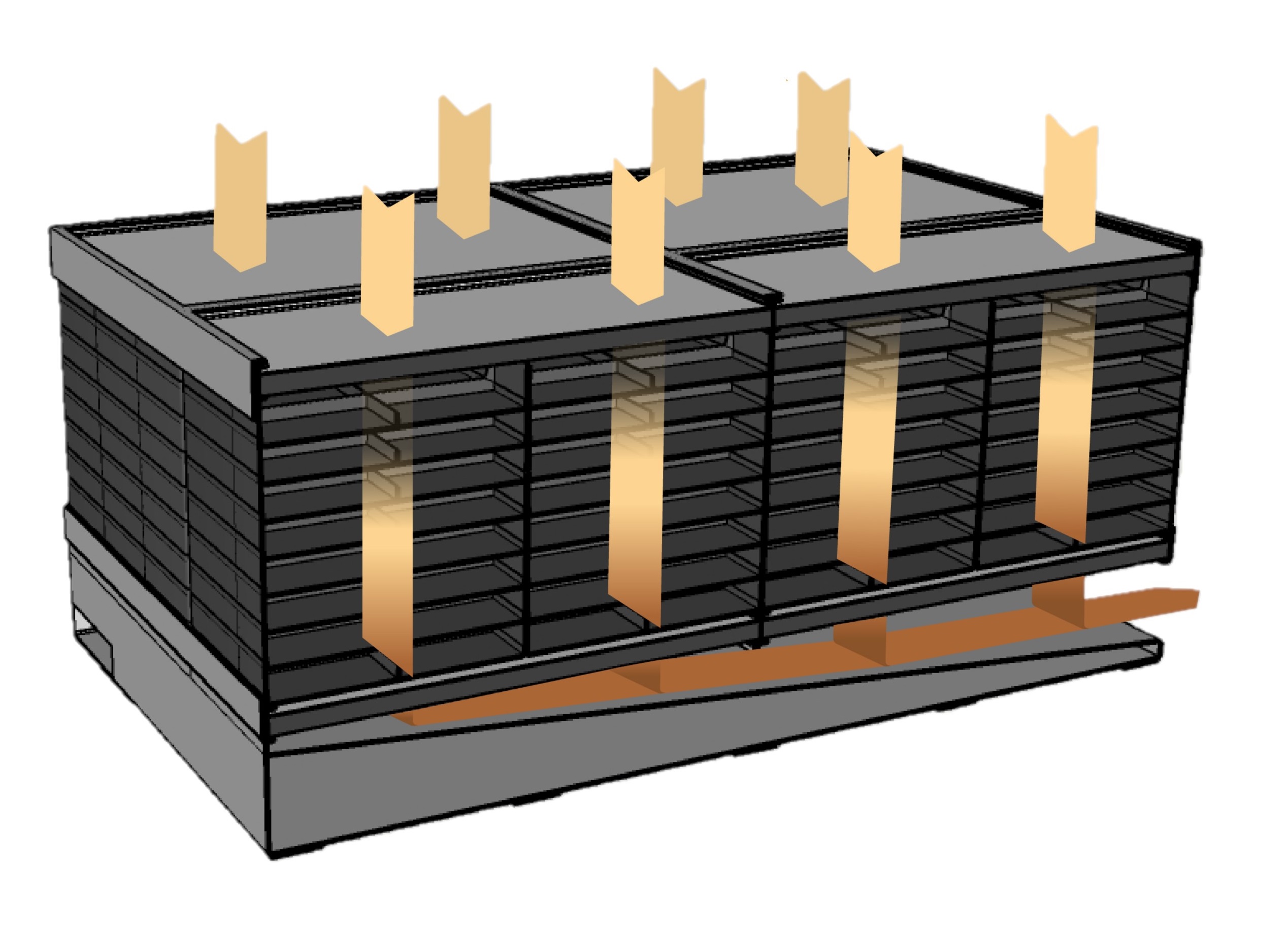

Top-down drying with a sandwich pallet

In a pallet sandwich, the filtered air goes top-down through the cannabis in a dark and clean environment.

Drying in this manner preserves the aromas, terpenes and cannabinoids.

Solutions for hang drying

A modulair Hang Drying Unit can be placed on the Ventilation Pallet.

- Racks are adjustable in heigth to make drying of branches or whole plants possible.

- The Hang Drying Unit can be placed on the same Ventilation Pallets as the Canna-Trays.

- The Ventilation Pallet with the Hang Drying Unit can be used in the same Drying Cell as the tray drying solution.

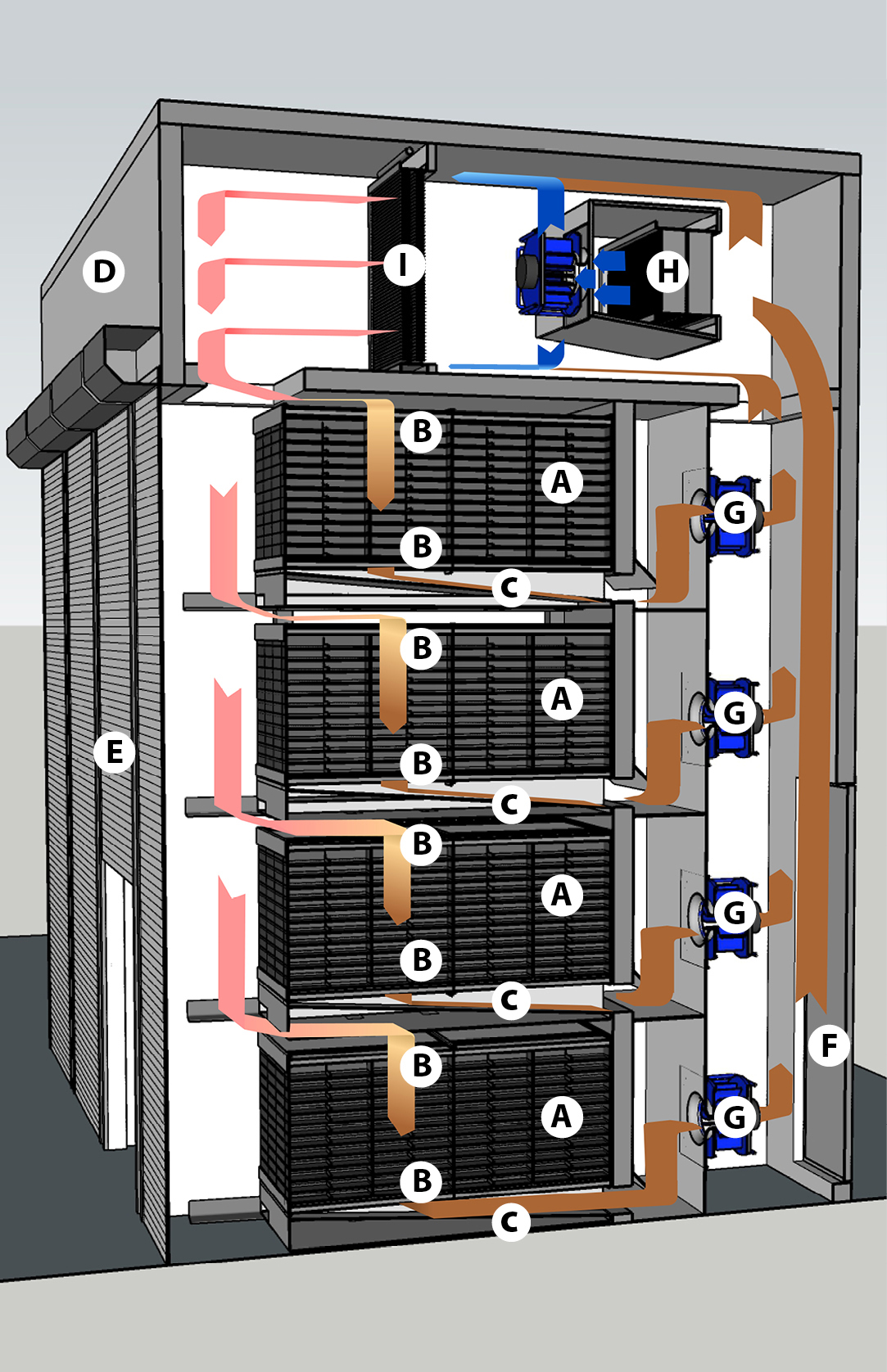

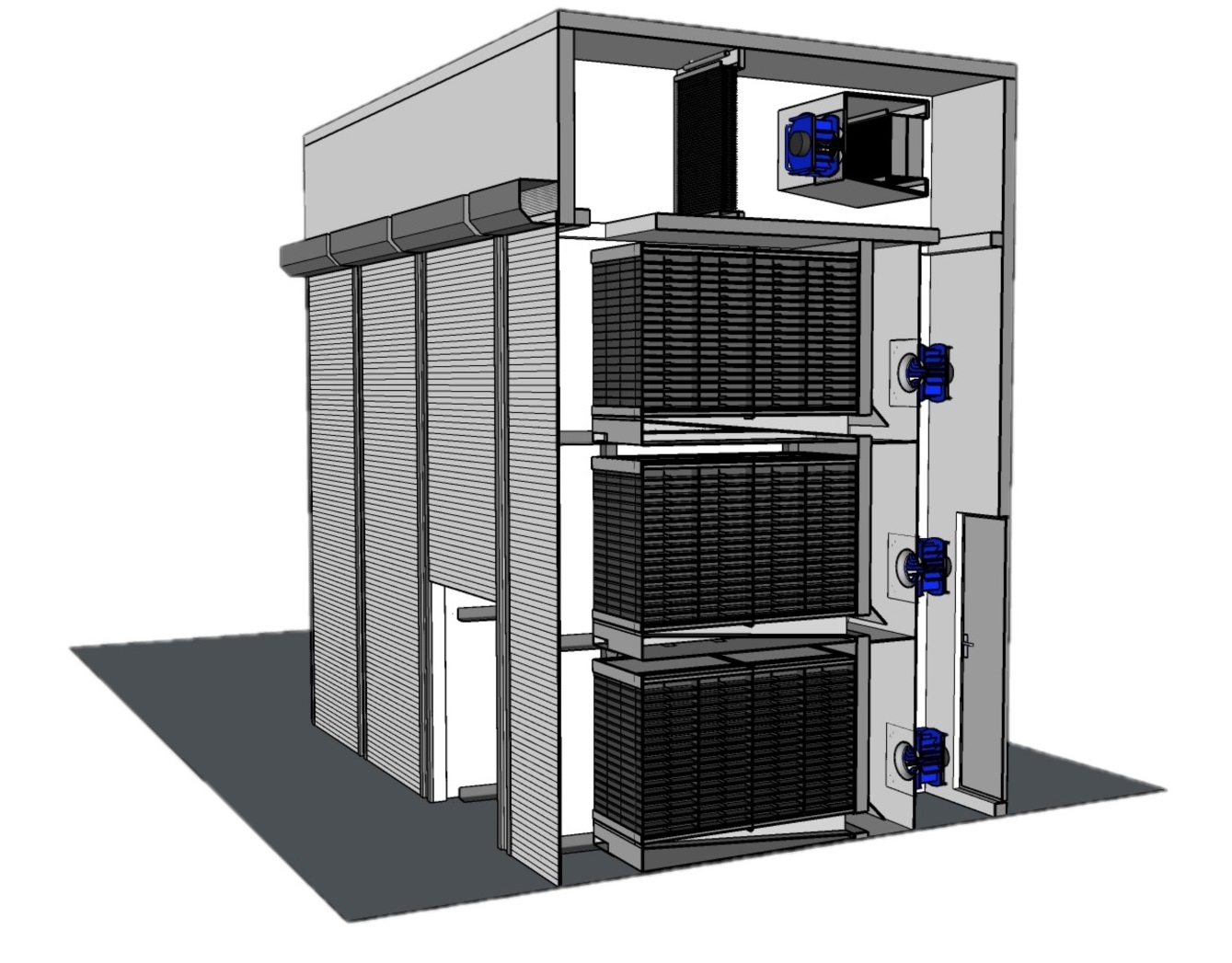

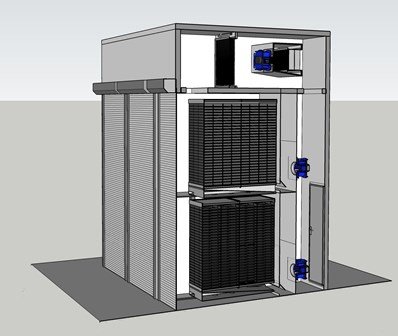

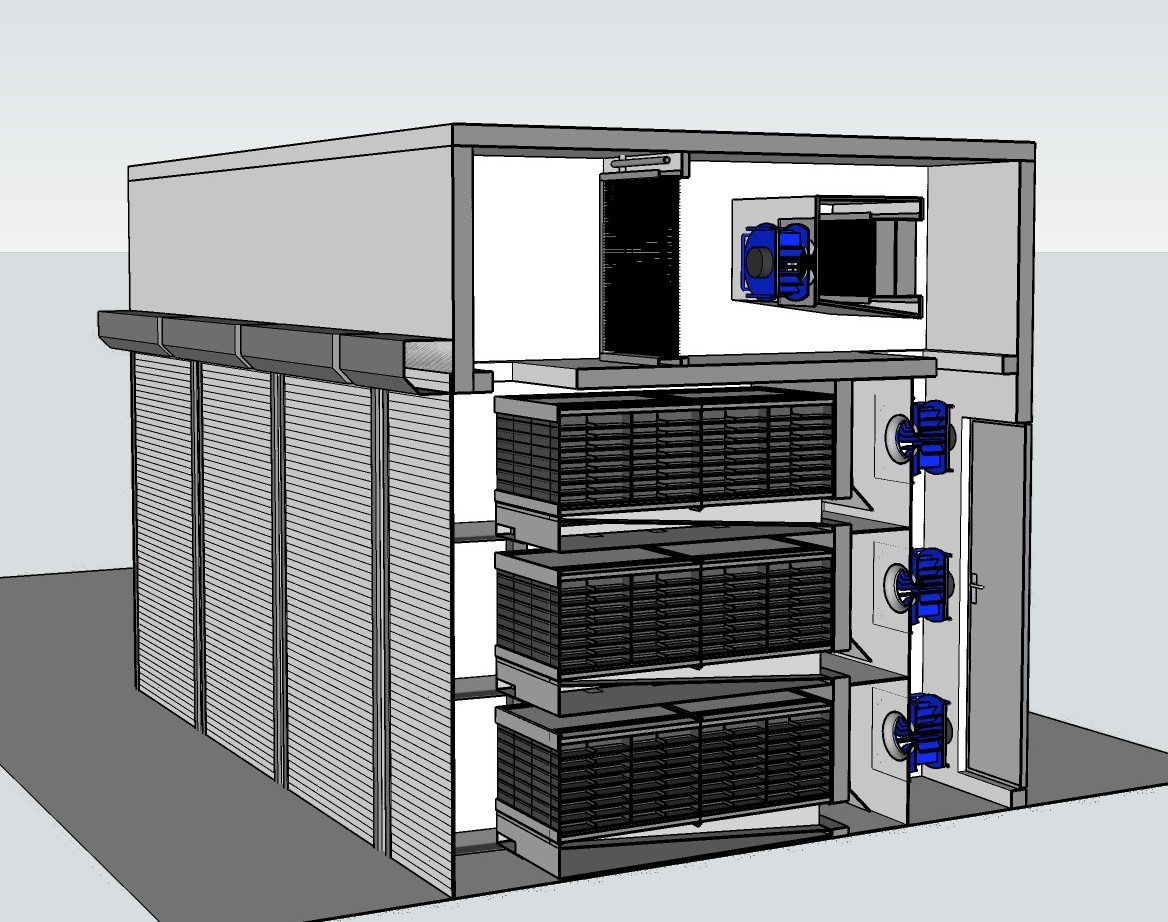

Components of a Drying Cell

Main parts of a clean drying cell

A, B and C: Pallet-sandwich consisting of cannabis trays (Canna-Trays (A), Filter sets (B) and a Ventilation Pallet(C)

D: Isolation panel

E: Roller shutter

F: Maintenance door

G: Ventilator

H: Condenser

I: Heater

How is the Drying cell used?

- A forklift driver, moving a sandwich unit, approaches the drying cell.

- On the ABC software the driver remotely (on a tablet) opens the roller shutter. Automatically, all devices in the drying cell turn off immediately.

- The driver places the pallet sandwich in an empty space.

- On the tablet, the driver closes the roller shutter of the drying cell. Automatically, all devices in the drying cell turn on.

- The manager controls the process on the led screen near the cell or remote on his/her device (tablet, pc, mobile phone or PC).

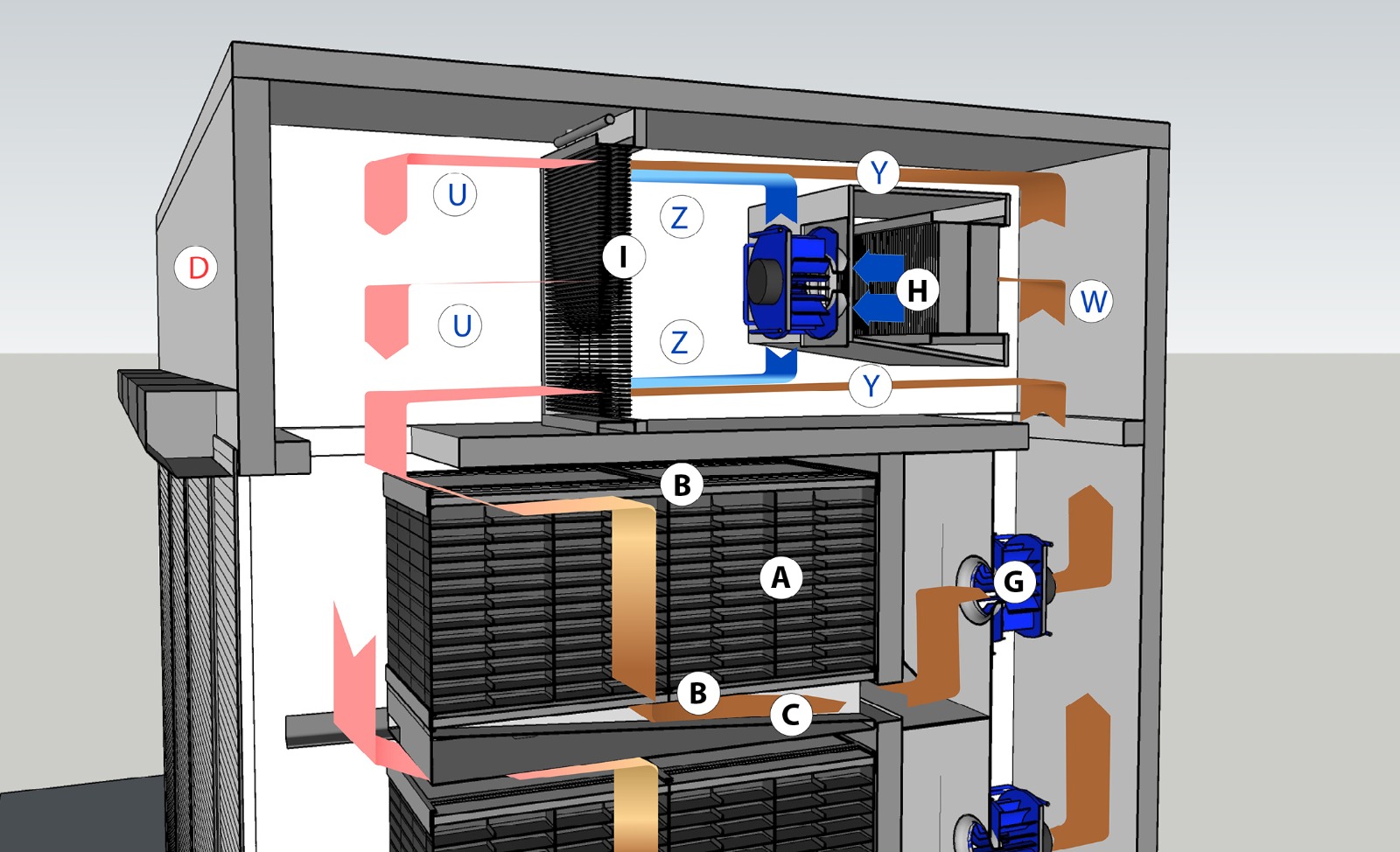

Drying Cell; how it works

The Drying cell – Details of How it Works

• The ventilator (G) sucks the process air (U) through the Canna-Trays (A), filters (B) and pallet (C).

• The air dries the cannabis and the absolute humidity of the air increases.

• A part of the wet process air (W) flows through the condensation unit (H).

• In the condensation unit (H), the air cools down and water condensates.

• The cooler air (Z) blends with the process air (Y).

• The blended air goes through the heater (I) where the air is again brought to the desired temperature.

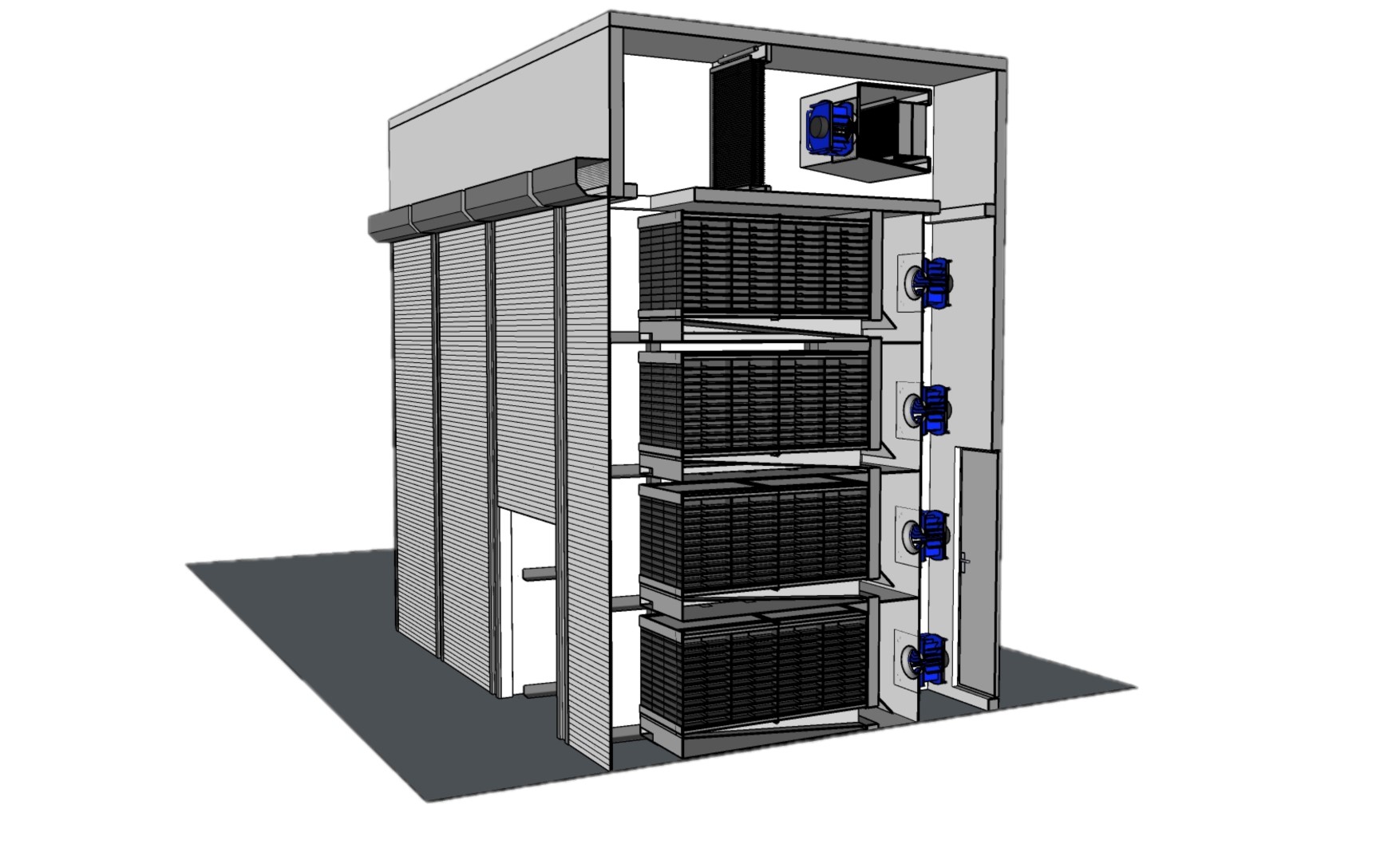

The size of the Drying Cell depends on your needs. The standard configuration is 5.24 meters (17.2 ft) high, 3.56 meters (11.7 ft) deep and 1.73 (5.7 ft) meters wide. The standard size is suitable for two to four Sandwich units.

A configuration with two Sandwich units has the highest capacity.

A configuration with four Sandwich units has a higher flexibility for your business operation.

Four Layer Drying Cell

4 pallet sandwiches

96 trays each unit

384 cannabis trays total

Three Layer Drying cell

3 Pallet sandwiches

144 trays on each unit

432 cannabis trays total

Two Layer Drying Cell

2 pallet sandwiches

232 trays per pallet sandwich

464 cannabis trays total

variety of sizes.

The amount of pallet sandwiches can vary from 1 to 5.

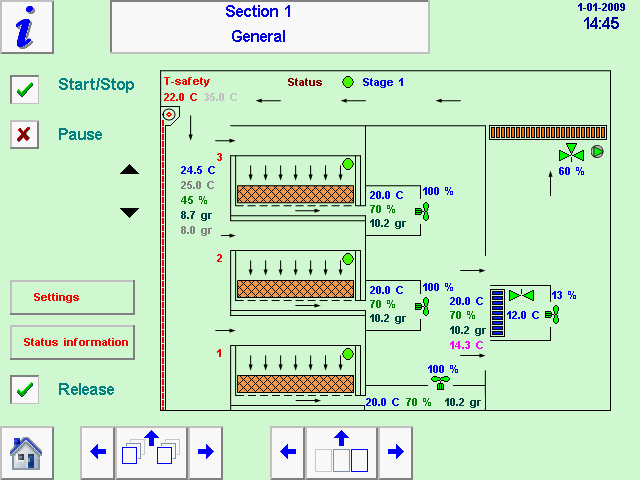

ABC-processor for the drying cell

- The ventilators are set at the desired amount of airflow, these can vary between the units.

- One sensor measures the temperature and relative humidity of the air that enters the units.

- Multiple sensors measure the temperature and relative humidity of the outgoing air of the pallet sandwich.

One sensor measures the air before it goes through the condenser and heater.

.

An ABC controller page of a drying cell