ABC - HVAC processor & The STAGES OF CANNABIS DRYING

In nature, everything wants to gain balance. When the humidity of an agricultural product like cannabis is high and the humidity of the airflow passing through it is low, the cannabis will release its moisture to the air. Thus, creating an equilibrium of moisture. When an equilibrium has been reached, moisture exchange is stopped. At this point, the cannabis will not dry any further, no matter how much airflow (of that same quality) passes through the cannabis.

So, with the correct temperature and RH (and therefore, the correct Absolute Humidity, AH), the cannabis will never become too dry. Consider that the drying of cannabis should not take place too fast.

Our ABC-processor allows you to set 5 stages of drying. In each stage, a different AH, airflow and temperature can be set. The next stage will only start after a set time and after reaching a set AH.

The ABC drying process is what we call ‘Optimal’, meaning it occurs gradually and at a certain speed.

The stages of Drying Cannabis

FIRST STAGE OF DRYING CANNABIS

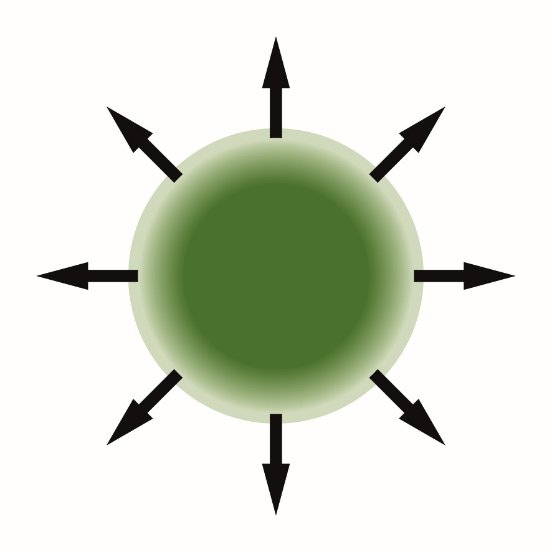

In the 1st stage of drying, it is important to remove the moisture on the outer layers of the cannabis as quickly as possible. This prevents activation of mold and bacteria.

With the ABC processor, this is realized by:

- Setting a large difference in moisture content (high delta AH) between the air and the cannabis for a short time.

- Creating an intensive air flow.

The 1st stage ends after a set amount of time.

1st stage: The external moisture of the cannabis is adsorbed by the air.

SECOND STAGE OF DRYING CANNABIS

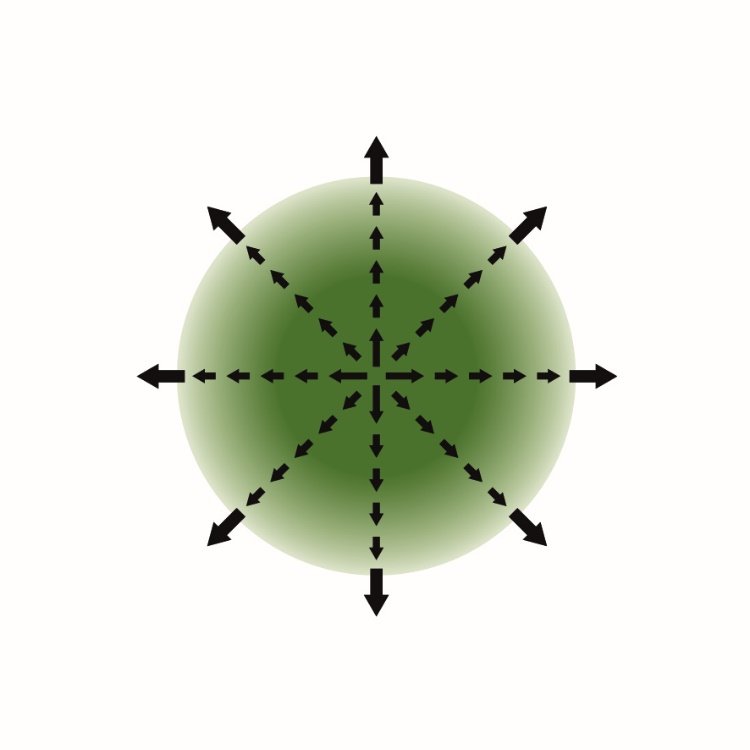

The first stage leaves a kind of disbalance of moisture between outer and deeper layers of the bud. The 2nd stage restores the balance between them, moisture in the core of the bud comes in equilibrium with the dryer outer layer.

The outer layer wants to come in equilibrium with the air, to make sure this process does not go to fast, a low Delta-AH must be set in the ABC processor.

The drying happens in a controlled and gradual manner. The moisture is adsorbed by less but more than enough air.

The whole unit with cannabis is dried top-down under control with an intensive airflow, evenly distributed in all layers.

2nd stage: The moisture balance in the cannabis is restored, the moisture content in each layer wants to be balanced. Ultimately, the core gets just as dry as the outer layer (and the air).

THIRD STAGE OF DRYING CANNABIS

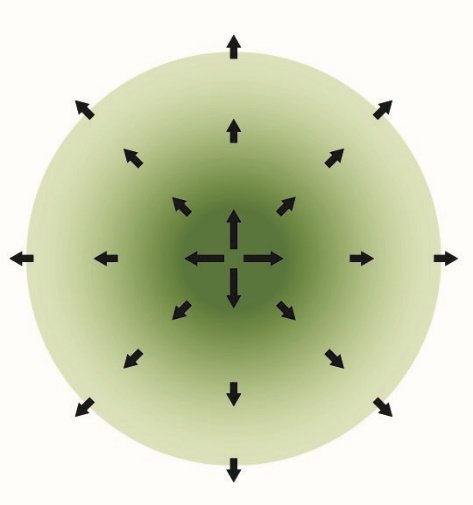

Only after a set minimum time is passed and a set AH is reached, the 3rd stage starts.

In the 3rd stage, the cannabis continues to be dried gradually by setting a lower Delta-AH.

FOURTH STAGE OF DRYING CANNABIS

To maintain the gradual drying, the Delta-AH is set even lower in stage 4.

3th and 4th stage: The moisture from the core of the cannabis moves to the drier exterior and is gradually adsorbed by the air.

FIFTH STAGE OF DRYING CANNABIS

In the 5th stage, the AH in the air reaches the desired equilibrium with the cannabis. It is the stabilizing stage.

In this stage, the air quantity decreases more and more to a minimum airflow. The moisture content of the cannabis is then completely stable; in the stems or buds and over all layers. At this point the Delta-AH is 0. The 5th stage ends after a set time.

End of the 5th stage: The moisture content in the cannabis is completely in equilibrium with the air.

CONCLUSION

- Due to the intensive airflow, the product dries evenly over all layers of the drying installation.

- Because a desired lower moisture content is set in each stage, the cannabis is gradually dried.

- A minimum drying time is set at each stage so that the cannabis has enough time to transform from CBGA to THCA, CBDA and CBCA.

- With the correct moisture content of the air per stage, the product never becomes too dry and dries evenly over all drying layers.

- With an optimal drying process, mold and bacteria are reduced to a minimum.

- The ABC processor enables this controlled drying in 5 stages:

- 1st stage: removes sufficient moisture to prevent the development of mold and bacteria.

- 2nd to 4th stage: gradually drying the product to a lower moisture content per stage

- 5th stage: achieving the desired moisture content of the cannabis.

- Each stage employs a set time, so that drying takes place in the desired time.

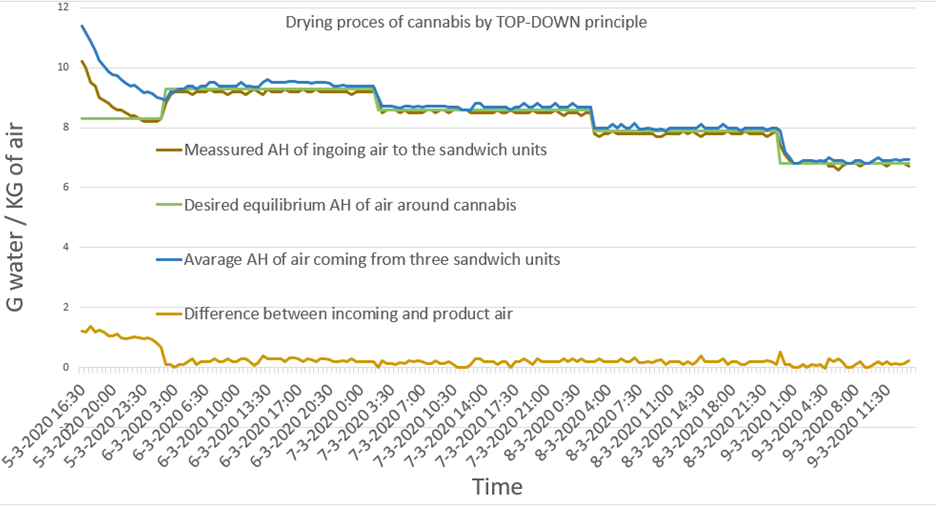

The graph shows that the desired AH is reached at an early part of each stage. The AH of the air coming from the three sandwich units quickly reaches a point where it is similar to the AH of the ingoing air to the sandwich units. The fact that the AH of the ingoing air is the same as the outgoing air, means that the cannabis does not dry any further. If the cannabis does not dry any further, the cannabis in the trays on the top will have the same moisture content as the cannabis in the trays at the bottom.

Note:

With the drying cabinets, mobile drying pallets and drying cells of Cannabis-drying.com, the desired air condition per drying stage is automatically achieved with the ABC processor.