Cannabis Drying Cabinet

Single Drying Cabinet

for 7kg of cannabis

A Drying Cabinet is used to dry small volumes of cannabis buds of around 7 kg / 15 lbs. of dried cannabis per drying cycle. Drying cabinets with a double capacity are available.

- Temperature and humidity are controlled with the ABC-processor.

- The amount of airflow can be easily set.

It is possible to control the drying cabinets with a control panel on the drying cabinets or with the ABC software on your phone, tablet or computer.

The drying cabinets offers space for 1 or 2 sandwich units.

For medical and recreational cannabis.

The drying cabinet can be used for curing as well.

Double Drying Cabinet

for 14 kg of cannabis

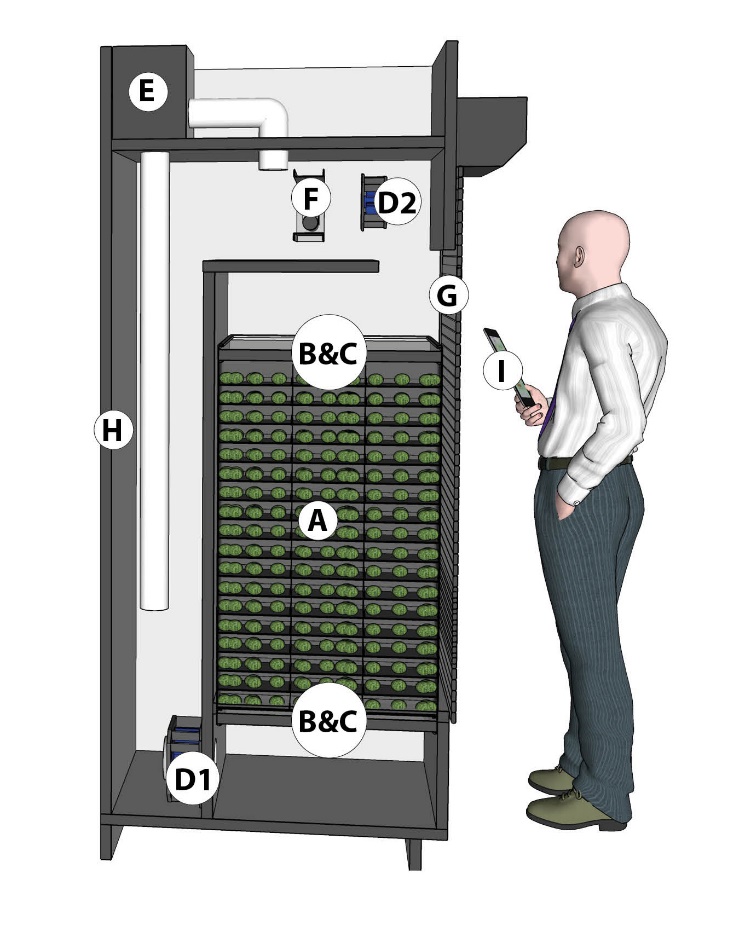

Components of a full drying cabinet:

| Single Drying Cabinet (7kg) | Double Drying Cabinet (14kg) | |

| A. | 36 Canna-Trays | 72 Canna-Trays |

| B. | 2 HEPA-Filters | 4 HEPA-filters |

| C. | 2 filter pads | 4 filter pads |

| D1. | First Ventilator | First Ventilator |

| D2 | Second Ventilator | Second Ventilator |

| E. | Adsorption Dryer | Adsorption Dryer |

| F. | Cooling Unit | Cooling Unit |

| G. | Airtight door | Airtight door |

| H. | Isolation panels | Isolation panels |

| I. | ABC-software on a tablet | ABC-software on a tablet |

| Size of the drying Cabinet | 985x905x1950mm (L39xW36xH77”) | 1970x905x1950mm (L78xW36xH77”) |

How is the drying cabinet used?

- The operator opens the door.

- Piles of Canna-Trays are placed on the HEPA filters & filter pads. (2 for single and 4 piles for the double cabinet).

- On top of the piles the HEPA-filters are placed.

- The operator closes the door.

- The operator activates and manages the drying process on the software of the remote device and / or on the touch panel.

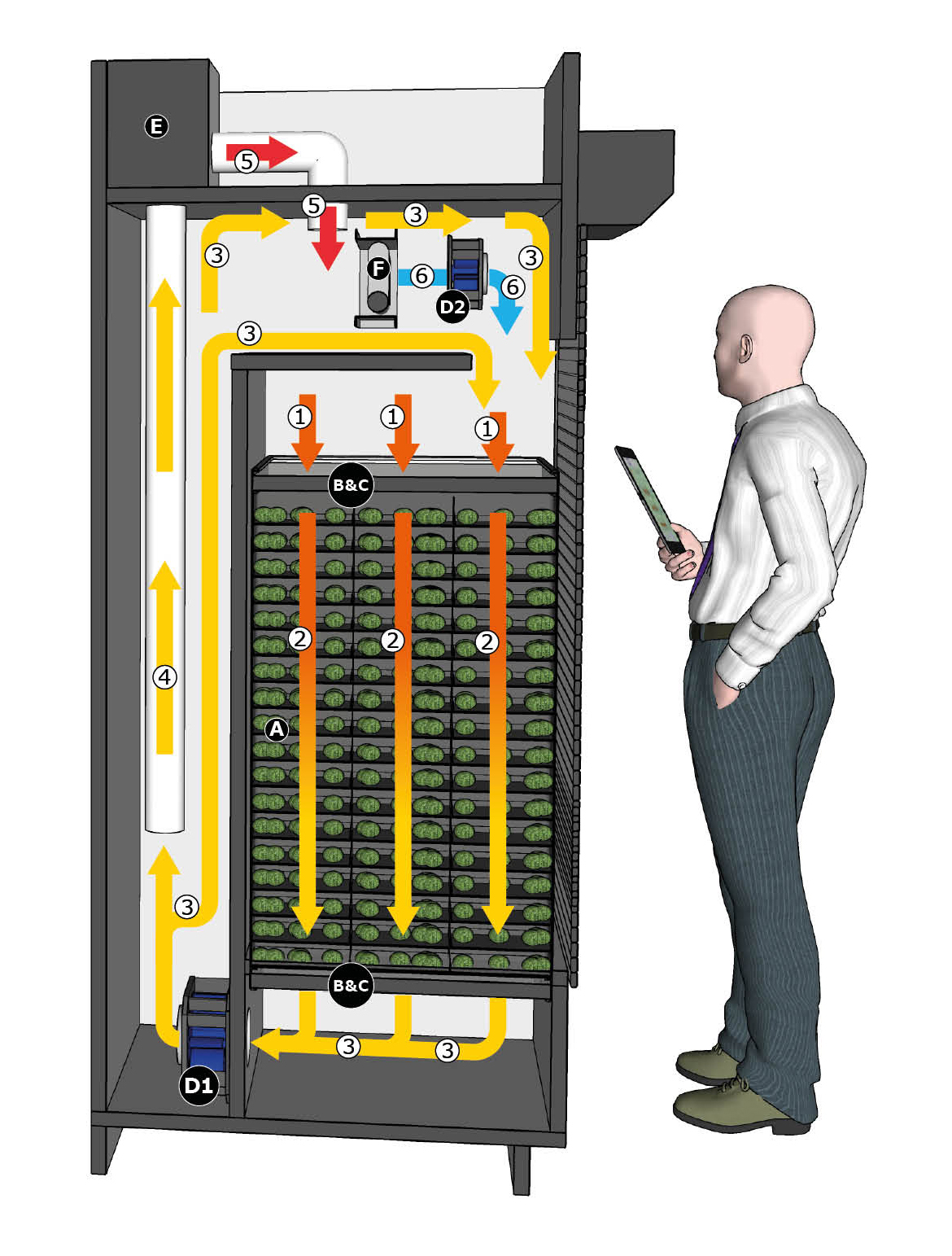

Drying cabinet – Details of how it works:

- The first ventilator (D1) sucks the process air (1) through the set of Canna-Trays (A) and filters (B&C).

- The air (2) dries the cannabis by adsorbing moisture from the cannabis.

- A part of this air (3) will circulate and enter.

- the Canna-Trays (A) again.

- Another part of the air (4) goes through the adsorption dryer (E) where the air heats up and water gets adsorbed from the air.

- The air from the adsorption dryer (5) mixes with the circulating process air (3).

- A part of this blended air (6) gets sucked through the cooling unit (F) by the second ventilator(D2) where the air is brought to the desired temperature again.

- The dried air (6) mixes with the circulating process air (3) and goes through the cannabis again. `