Mobile Drying Pallet

A Mobile Drying Pallet is used to dry large volumes of cannabis buds in an existing or new drying room.

The main difference with traditional cannabis drying methods is that the air is sucked top-down through the product by a ventilator, instead of blown over the product. Top-down drying results in an evenly dried end-product.

For medical and recreational cannabis.

In the Mobile Drying Pallet, 4 sandwich units are placed. The Mobile Drying Pallet is designed in such way that the air is evenly distributed over the different piles of Canna-Trays.

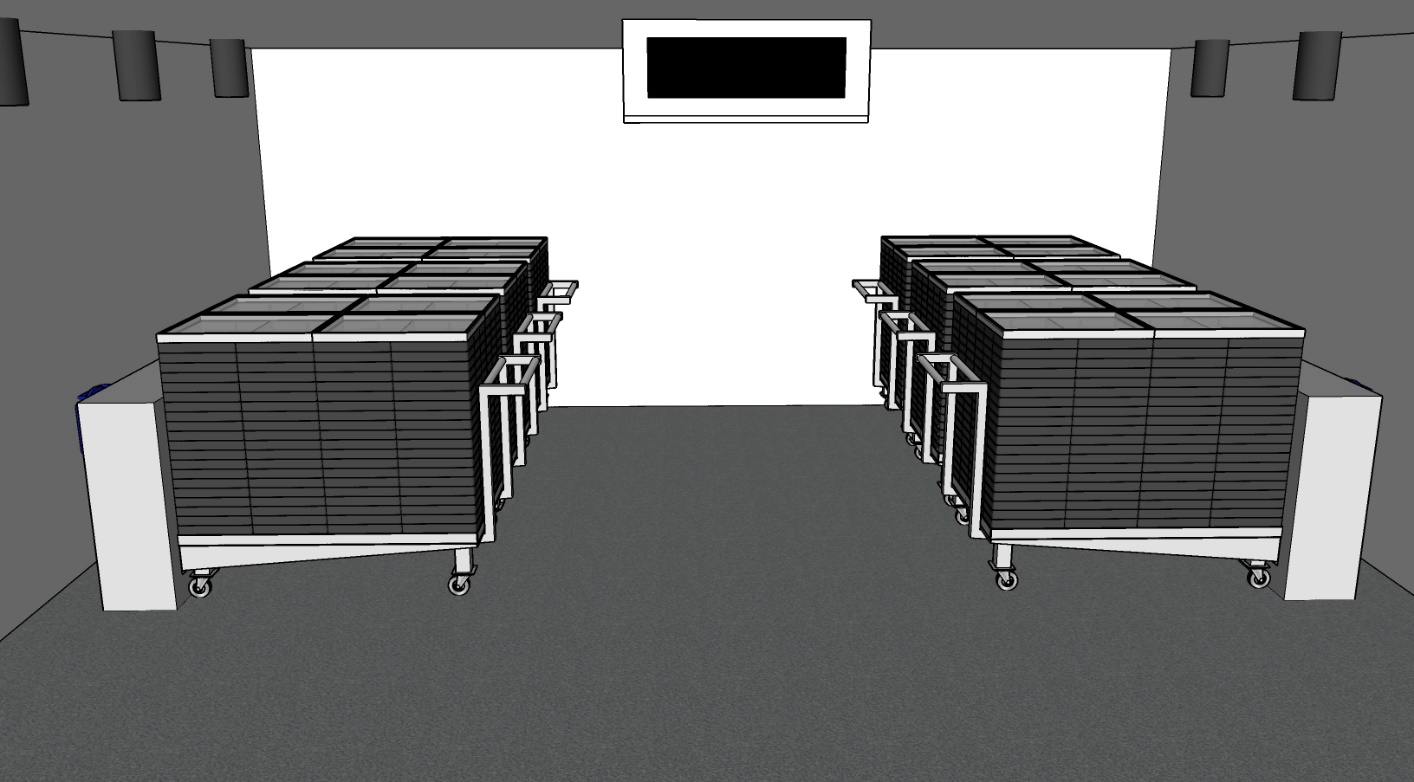

One Mobile Drying Pallet is capable of drying 32kg (71lbs) per drying cycle. A drying room can be filled with 1 to 12 Mobile Drying Pallets.

How is the Mobile Drying Pallet filled?

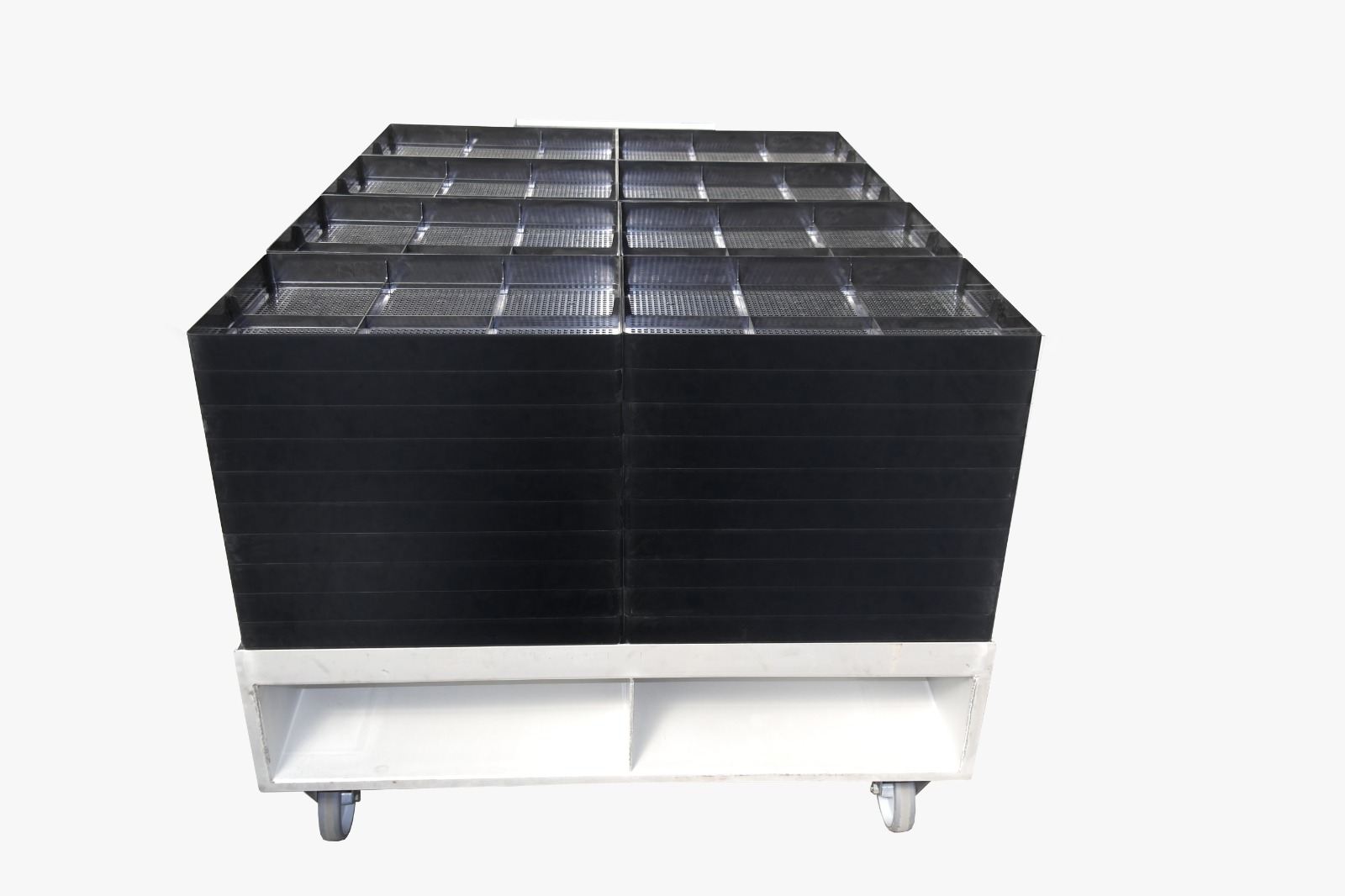

- 4 filters are placed at the bottom of the Mobile Drying Pallet.

- 8 piles of Canna-Trays are placed on the filters.

- 4 filters are placed on the piles of Canna-Trays.

Overview of a drying room filled with Mobile Drying Pallets

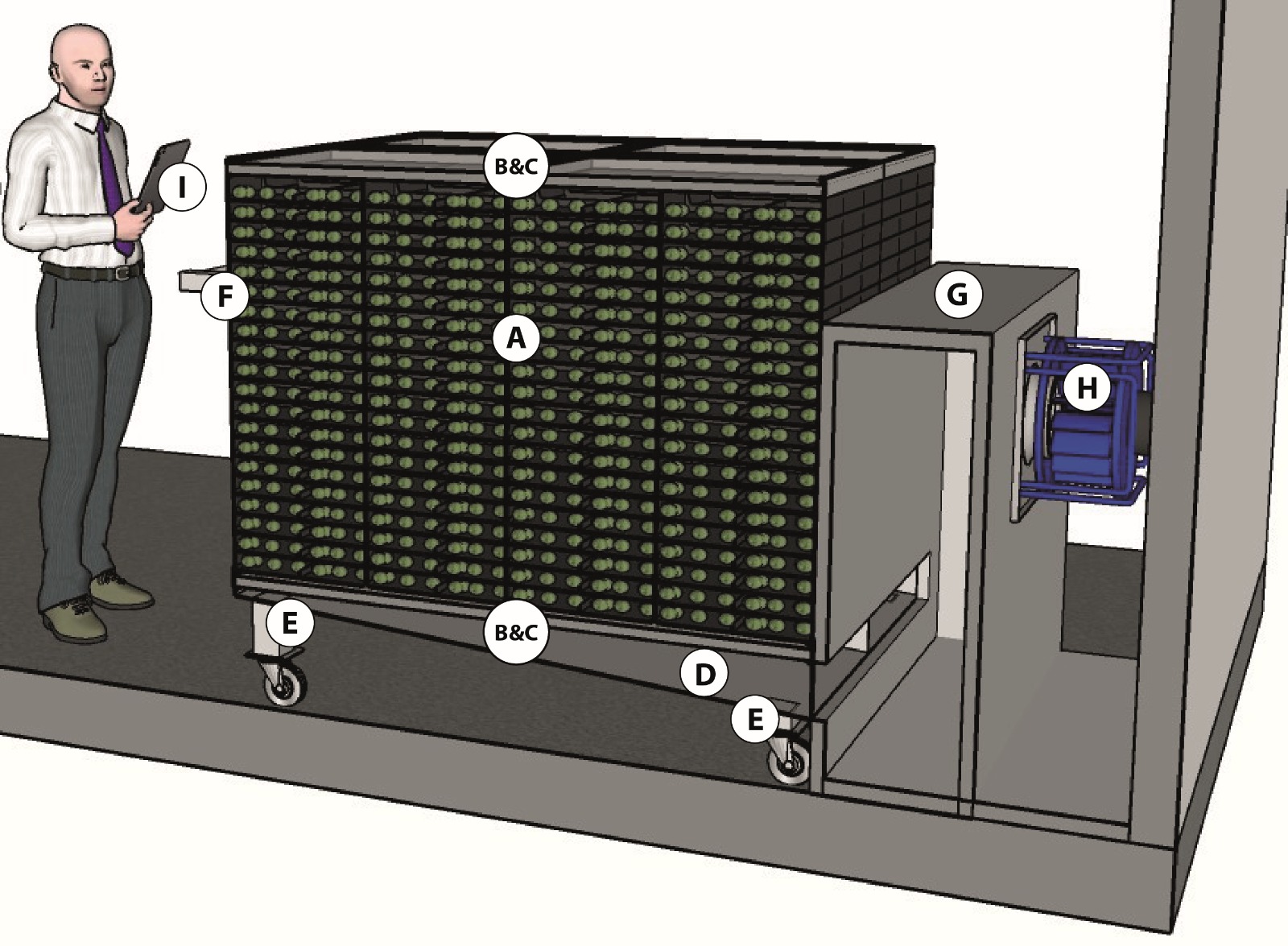

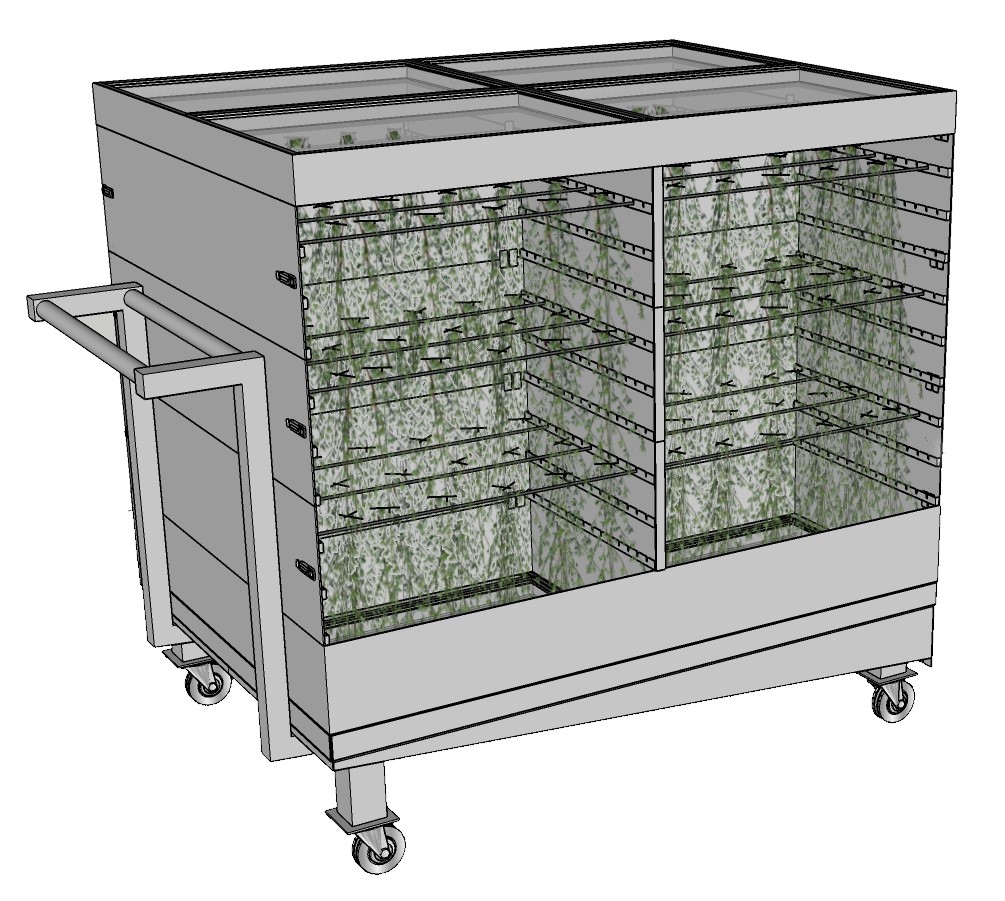

Transparent view of the Mobile Drying Pallet

Components of a full Mobile Drying Pallet (32 kg of dried cannabis)

A. 160 Canna-Trays

B. 8 HEPA-filters

C. 8 filter pads

D. Ventilation Pallet

E. 4 wheels with brakes

F. Handgrip

G. Plenum

H. Ventilator (placed in the plenum)

I. ABC software on a tablet

Size of the Mobile Drying Pallet (filled with sandwich units): L1610x W1210x H 1600 mm (L63.4 x W 47.6 x H 63”)

Solutions for hang drying

A modulair Hang Drying Unit can be placed on the Mobile Drying Pallet.

- Racks are adjustable in heigth to make drying of branches or whole plants possible.

- The Hang Drying Unit can be placed on the same Mobile Drying Pallet as the Canna-Trays.

- The Mobile Drying Pallet with the Hang Drying Unit can be used in the same drying room as the tray drying solution.

–

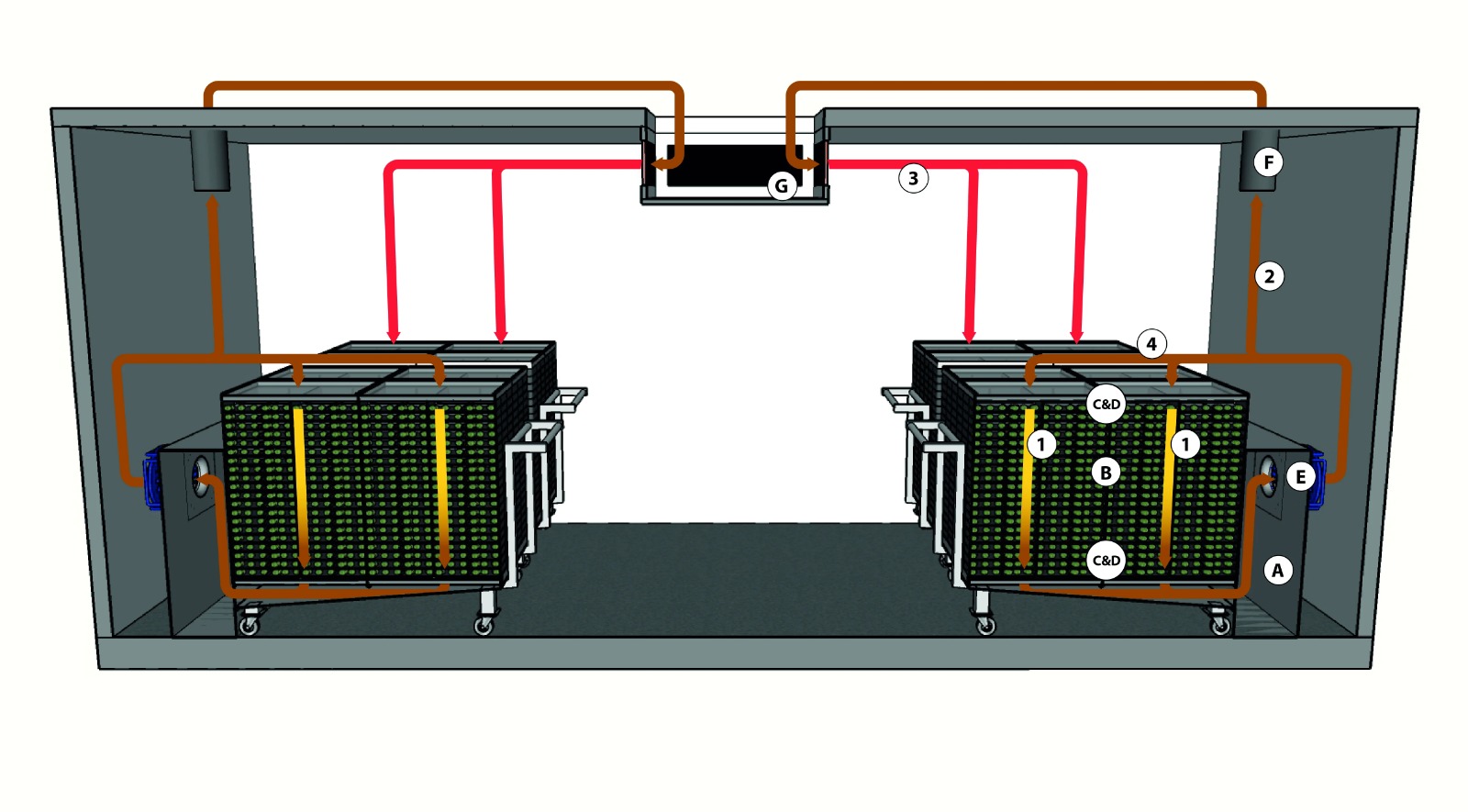

Mobile Drying Pallet – Details of how it works:

- The Mobile Drying Pallet is placed against a plenum (A).

- The ventilator in the plenum (E) sucks the process air (1) through the Mobile Drying Pallets.

- The process air (1) goes through the filters (C&D) and the Canna-Trays (B) where it dries the cannabis by adsorbing moisture.

- A part of the wet process air (2) goes through the tubes (F) towards the conditioning unit (G).

- In the conditioning unit (G), water is extracted from the air by condensation and then reheated to the right temperature.

- This conditioned air (3) mixes with the circulating process air (4).

- The mixed air is at the desired temperature and humidity again and enters the Mobile Drying Pallets (1).